Zero-Liquid-Discharge Dyeing: How Shazhou Closes the Water Loop

Source:联系-果博东方福布斯电话17787599998(果博东方开户 客服 上下分) Release time:2026-01-08 10:57:32 Author:94

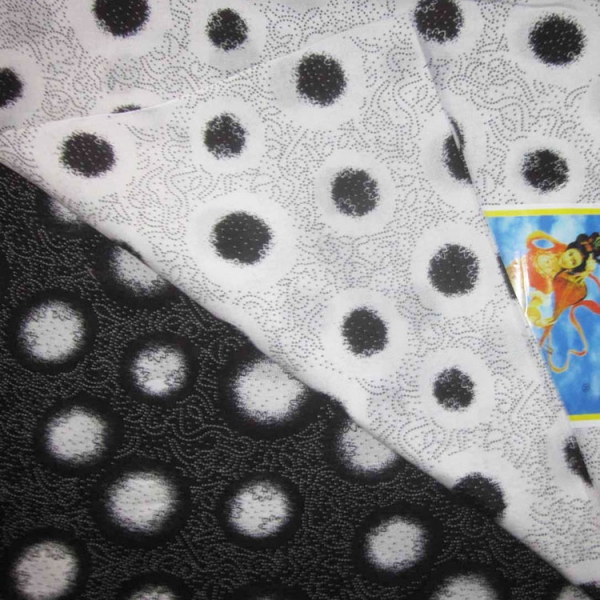

Zero-liquid-discharge dyeing—known across the textile industry as ZLD—is rapidly transforming how fabrics are produced in China and around the world. As fashion buyers push for greener sourcing and governments tighten environmental rules, textile mills must rethink traditional water-intensive processes. For Shazhou Textile, ZLD is not simply a compliance requirement—it is a strategic decision to protect natural resources, support long-term manufacturing stability, and lead the industry with a cleaner way of dyeing. The term zero-liquid-discharge refers to a closed-loop water management system in which no wastewater is released into rivers, drains, or open land. Instead, all water goes through deep filtration, biological breakdown, recovery, evaporation, and eventually re-enters production. This eliminates pollution and drastically reduces total water intake. For an 800,000 m² textile facility like Shazhou, which handles hundreds of production batches every week, adopting a ZLD system means unprecedented environmental control. It ensures that every drop of water is accounted for and reused responsibly.

The ZLD cycle begins the moment used dye bath water exits Shazhou’s dyeing machines. Traditionally, this wastewater contains dyes, pigments, salts, finishing agents, and organic compounds that are harmful if released untreated. At Shazhou, this water flows directly into a multi-stage treatment line. The first step involves mechanical sieving and sedimentation. Here, threads, lint particles, and large suspended impurities are separated. While this stage represents basic filtration, it plays a critical role in stabilizing downstream processes and preventing damage to advanced filtration membranes. Once primary filtering is completed, the second stage combines coagulation, flocculation, and dissolved air flotation. Chemicals are added, causing invisible dissolved impurities to gather into removable clusters. These clusters float or sink and are extracted from the water stream. This prepares the remaining liquid for deeper treatment. Shazhou treats wastewater as a resource, not waste, and each step is engineered to protect that resource while removing contamination systematically.

After physical pretreatment, the wastewater enters biological reactors. Inside, carefully balanced microbes consume organic matter such as soaps, oils, dispersing agents, and sizing chemicals. This phase mimics nature’s decomposition process but at a controlled industrial scale. Once biological treatment reduces organic loads, water flows into advanced ultrafiltration and reverse osmosis systems. These membranes separate microscopic dye molecules, salts, and dissolved solids that previous stages could not remove. What emerges from these filters is clean, clear water ready for reuse. However, ZLD doesn’t stop with reverse osmosis. The remaining concentrated brine—usually considered unusable—is sent to evaporators and crystallizers. Heat turns water molecules into steam, leaving solid residues behind. Once condensed, that recovered steam becomes clean distilled water. The solid waste, now dry and compact, is processed further for safe disposal or repurposing into industrial by-products where possible. At this point, zero liquid remains, fulfilling the system’s purpose and ensuring no discharge into natural ecosystems.

Shazhou redirects recovered water back to dyeing machines, rinse systems, and cleaning operations. Reusing water in production offers several benefits beyond environmental protection. Recycled water is chemically consistent, improving dye uniformity, shade accuracy, and colorfastness performance. Because it contains fewer mineral variations than municipal water, batches become more predictable, reducing rework and saving energy, dyes, and auxiliary chemicals. The plant becomes more efficient, more stable, and more profitable while reducing its footprint. Investing in ZLD requires commitment, technology, and expertise, but the long-term gains are clear. Shazhou reduces freshwater demand, eliminates contamination risk, strengthens compliance with global fashion brand audits, and supports communities by protecting local river systems. Customers worldwide increasingly prefer suppliers that can demonstrate real sustainability—not just in marketing language but in measurable operational practice.

ZLD is only one part of Shazhou’s larger sustainability roadmap, which includes upgraded dyeing chemistries, optimized heat recovery, and reduced carbon output. Yet it symbolizes a major turning point for textile manufacturing: a shift from linear resource use toward circularity. By closing the water loop, Shazhou proves that large-scale production and environmental responsibility can reinforce—not oppose—each other, setting a new standard for clean textile dyeing.